NEW!

HOLLOW-PRO M4 Scrapers now

available in a longer EXTENDED version!

For situations where you

need a little extra reach, with both

the straight and bent, 1/2" and 5/8" tools.

|

Now Available in Standard and Large Sizes!

Blast

the Wood Out of Small, Medium, and Large Hollow Vessels!

5" Diameter Natural Edge Masur

Birch Hollow Form Turned Using Hollow-Pro Rocket Tools

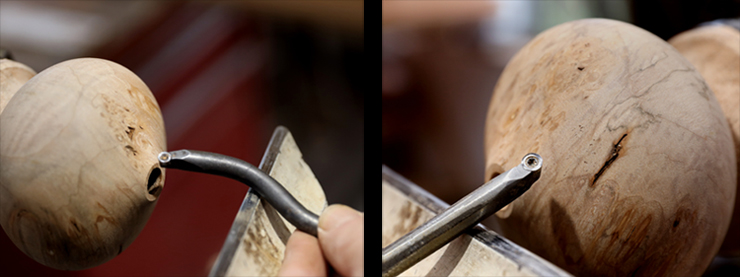

Rocket Tools at Work

photos by Chris Bossardet

|

HOLLOW-PRO ROCKET

Standard size tools are professional, fast and efficient

hollowing tools for making hollow vessels up to about 7"

high x about 7" diameter. These 8" tools have 3/8" shafts to

allow hollowing through very small, restricted openings. The

tools use replaceable #1 size carbide cutters and are

designed to fit into any large handle with a 3/8" or 1/2"

opening. (Tip: place the screws from these handles on the

side or top of the tools, so the bottom will slide smoothly

on the tool rest)

NEW! HOLLOW-PRO

LARGE ROCKET TOOLS

Blast the wood out of

medium/large size hollow vessels!

HOLLOW-PRO LARGE ROCKET

tools are now available for making hollow vessels up

to about 10" high and about 10" in

diameter. These 11" tools have 1/2" shafts that facilitate

hollowing through small restricted openings. LARGE

ROCKET tools use #1 carbide cutters and are designed to fit

into any large handle with a 1/2" opening. (Tip: place the

screws from these handles on the side or top of the tools,

so the bottom will slide smoothly on the tool rest.)

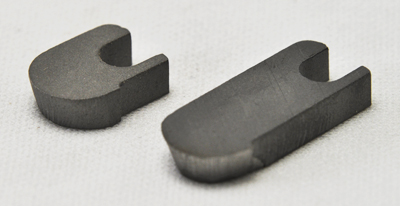

The round shafts of these tools can be rotated slightly to make clean "shear" cuts and the bent tool is also very useful for undercutting the openings on larger hollow vessels. Set of one straight and one bent tool includes replaceable Hunter #1 carbide cutters for clean cuts and durability, and a Torx wrench for rotating and replacing the cutters as needed. Notes On Use of Hollow-Pro Rocket Tools The Hollow-Pro 3/8" and 1/2" ROCKET straight tools are very versatile tools that can be used to remove wood quickly and easily from hollow vessels and open bowls. They also work very well for hollowing out boxes. BENT TOOLS: The Hollow-Pro 3/8" and 1/2" ROCKET bent tools were designed to hollow vessels up to about 7" (for the 3/8" tool) and up to about 10" in diameter (for the 1/2" tool), but they are also intended to be used on larger pieces. By using the smaller tools to undercut the first portion of larger vessels, the tool rest is closer, resulting in a cleaner cut and greater control. _______________________________________________________

|

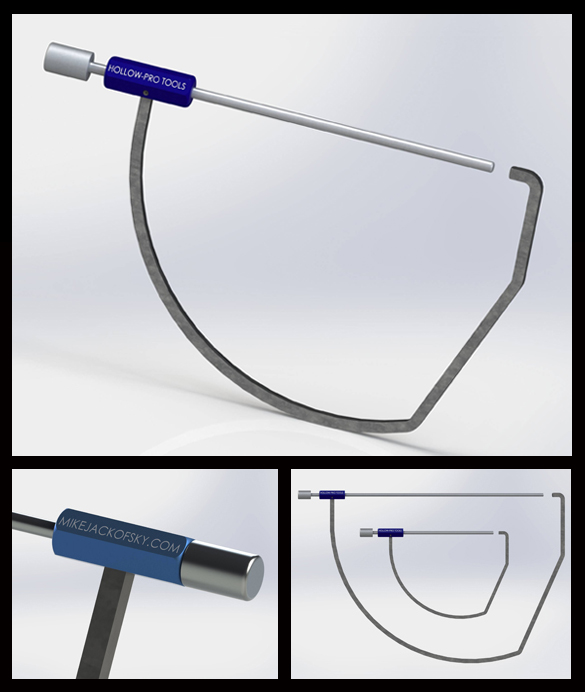

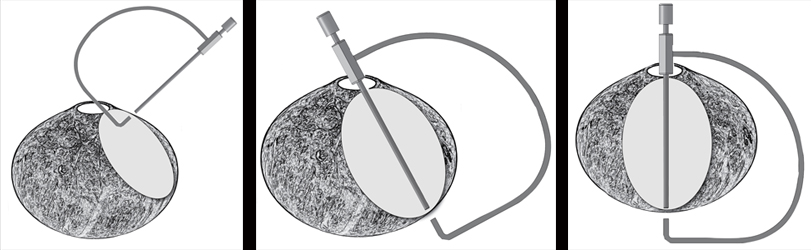

Hollow-Pro High Quality Calipers

Copyright

2012, 2013 Mike Jackofsky -

All Rights Reserved

Website

design by Rick Jackofsky